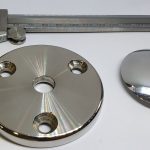

The components produced by us, are manufactured on modern multi task CNC turning machines. A high degree of automation enables rational and fast production time. Due to the large vertical range of manufacture and our own tool and fixture construction, we can react flexibly to customer requirements.

Small series: 100 – 1.000 pieces

Medium series: 1.001 – 20.000 pieces

Large series: 20.001 – 500.000 pieces.

Whether small or large series – we endeavour to make every product solution possible and will be pleased to make you an individual offer for your turned parts.

Larger quantities can also be produced after consultation.

Multi task CNC equipment for Turning parts with milling operations:

- CNC HAAS DS30-Y – 5axis with bar feeder LNS Q.Servo III,

- CNC HAAS ST20-Y – 5axis with bar feeder LNS Q.Servo III

- CNC Mazak QTN 200M – 3axis with bar feeder LNS Q.Servo III,

- CNC Mazak QT6T – 2axis with bar feeder Fedek 65L,

- QuickTech I42E – 4axis with bar feeder LNS Q.Servo II,

- QuickTech I42E – 4axis with bar feeder LNS Q.Servo III,

- QuickTech I42E PLUS B – 6axis with bar feeder LNS Q.Servo III,

- QuickTech I60E PLUS B – 6axis with bar feeder LNS Q.Servo III

- QuickTech I42U – 10axis with bar feeder LNS Q.Servo III

- QuickTech I42U+B – 12axis with bar feeder LNS Q.Servo III

- QuickTech I60U+B – 12axis with bar feeder LNS Q.Servo III

(The “I-42 and I-60 Ultimate” machines, designation comprises of 10-12 axis and 4 spindles which includes a sub spindle with both X and Z positioning. This also marks the integration of the driven tools having a powerful B- axis milling for simultaneous and efficient machining. Due to this enhancement, the tools application becomes more fast and flexible for complicated parts.)

- 25 Conventional Automatic Lathes, TRAUB A25-TB80, with 3m bar feeders,

- 8 NC long turning NOMURA lathes with 3m bar feeders,

- 4 long turning Tornos-Bechler lathes with 3m bar feeders,

- Hand lathe Tos Trencin 2m long.

Equipment for surfaces:

- 1 Ultrasonic cleaning machine,

- 1 Vibration polishing machine with stainless steel balls,

- 1 Vibration polishing and deburring machine.

Various machines:

- 2 Rolling press machines SENY (Knurling, threading),

- Automatic wire forming machine JH – 250 capacity till 4mm,

- 2 automatic wire forming machines capacity till 10mm,

- 10 drilling and threading machines for supplementary works,

- 1 grinding Santerlat.

- 2 automatic band saw machines.

- 1 Material Hardness tester, portable equipment

Measuring Equipment:

- 1 Video Measuring System (optical automatic 3D measurements)

- 1 Digital projector-microscope.

- Many Go no go certified gauges (rings, plugs etc)

- Many Mitutoyo digital micrometers 0,001mm up to 500mm.

- 1 TESA Granite Table

- Many TESA certified digital calipers 0,01

Drawing development:

- 1 Solid CAD-CAM (turning and milling operations)